Basic Info

Model No.: NTR260

Click on the follow link to find out more information: https://www.nhgtunnel.com/tunneling-roadheader/

Company Info

- Company Name: NORTH HEAVY GRYPS EQUIPMENT AND ENGINEERING CO.,LTD

- Representative: JU KUNPENG

- Product/Service: Mining Roadheaders , Tunneling Roadheaders , Drilling Jumbos , Drilling Rigs , Bolter Machines , Continuous Miners

- Capital (Million US $): 20,000,000 RMB

- Year Established: 2013

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: above 20

- No. of R&D Staff: 91 -100 People

- No. of QC Staff: 91 -100 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: 5-1 Tianci Street,Hunnan District, Shenyang,110000, PRC

- Contact Person: Ms. Lily Zhang

- Tel: 86-13998186634

Premium Related Products

Hot Products

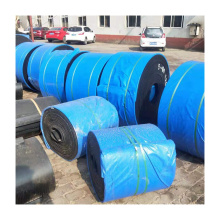

High Performance Steel Cord Conveyor BeltMetal-reinforced TBM ST6300 Steel Cord Conveyor BeltXe-Sc+1 Type Sidewall Corrugated Rubber Conveyor BeltTBM-purpose ST7500 Steel Cord Conveyor Belt DurableTear Resistant Steel Cord Rubber Conveyor BeltTBM ST5000 High-strength Steel Cord Conveyor BeltSidewall Conveyor Belt Steep Incline CorrugatedPVC PVG Flame-retardant Solid Woven Conveyor BeltAcid & Alkali Resistant Rubber Conveyor Belt Corrosion ResistantTear Resistant Steel Cord Rubber Conveyor BeltEndless Ring-shaped Conveyor BeltPatterned Conveyor Belt Chevron-patterned Special Patterned BeltMulti-ply EP Rubber Conveyor Belt Material HandlingMulti-ply Fabric Conveyor Belt EP NNSteeply Incline Sidewall Conveyor Belt Rubber Products25km High Performance Tbm-Purpose Steel Cord Conveyor Belt