Wear Resistant New Technology Composite conveyor roller

Basic Info

Model No.: HS-0180101

Product Description

Composite Material Conveyor roller

Composite Conveyor Roller Advantage:

- Excellent Wear resistance

- Excellent Long Service Life

- Patented Products

- Lower Noise

- High Anti-Magnetic Properties

- Effective sealing system

- Light weight and energy saving

- Reduced belt damage

- Corrosion resistance

- Impact resistance and Impact energy absorbing

Composite conveyor idler are used to convey bulk material with belt.Roller and bearing housing are by special double end boring machining. The machine adopts double cutter, double system control, single knife adjustment, a clamping and cutting independent ends. Non tolerance tight fit assembly of roller body and bearing seat, processing concentricity is less than 0.02mm.

we could produce the idlers in both Metric and Imperial CEMA standards or any other custom size

Composite Material Conveyor Roller Features:

Belt conveyor systems are widely used in mining, metallurgy, ports, thermal power and cement industry and so on. Conveyor rollers and conveyor pulleys are the most important consumption parts of belt conveyor system, their working life and performances have a huge influence on conveyor efficiency and the conveyor system cost.

1.Patented products

2.Excellent abrasion/ wear resistance

3.Excellent corrosion resistance

4.High Anti-magnetic/ excellent non-magnetic properties

5.Low friction coefficient/ low coefficient of friction

6.Low noise (60-70bd)

7.Long life is more than steel roller 6-8 times

8.Light weight and energy saving

9.Outstanding Anti-Acidic/Anti-Alkaline/ Anti- Static

Wide Application

Our Composite Material Conveyor Roller can widely applied for mining, coal ,metallurgy,electric power, wharf and sea port, grain,chemical and almost any industry which have conveying system.

Different type of conveyor idlers

1. Flat/Carrier/Carrying Rollers: Used to handle bulk & unit material.

2.Impact Rollers: Installed at the loading point to absorb the shocks and to help protect against belt damage.

3.Return Rollers: Used to sustain and support the belt during its return section and performs a cleaning action

Return Rollers with Spaced Rings (Rubber Disc Rollers)

Return Rollers with Helical Rubber Rings (Spiral Rollers)

4. Self-aligning/Training Rollers: Used to adjust the belt deviation, preventing hunting and ensuring stable operation of Conveyor Belt.

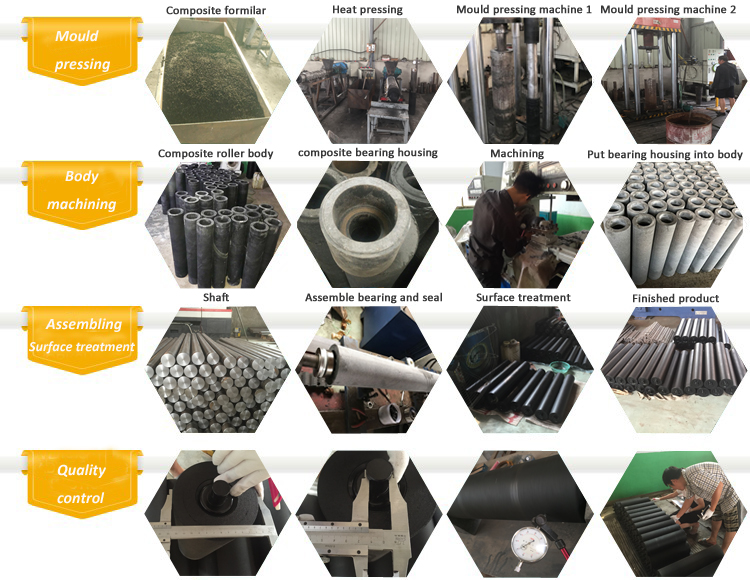

Conveyor roller Composite Roller body and bearing seat processing

Composite Material Conveyor Roller and bearing housing are by special double end boring machining. The machine adopts double cutter, double system control, single knife adjustment, a clamping and cutting independent ends.Non tolerance tight fit assembly of roller body and bearing seat, processing concentricity is less than 0.02 mm.

Composite plastic conveyor idlers compare with other material idlers

Our Composite Material Conveyor Rollers working life is 8-10 times longer than steel rollers.The price is 2-3 times higher than steel rollers. But for users, the cost of composite roller cost is only 1/5-1/4 of the cost of steel roller. So the composite roller price and performance advantages are very competitive.

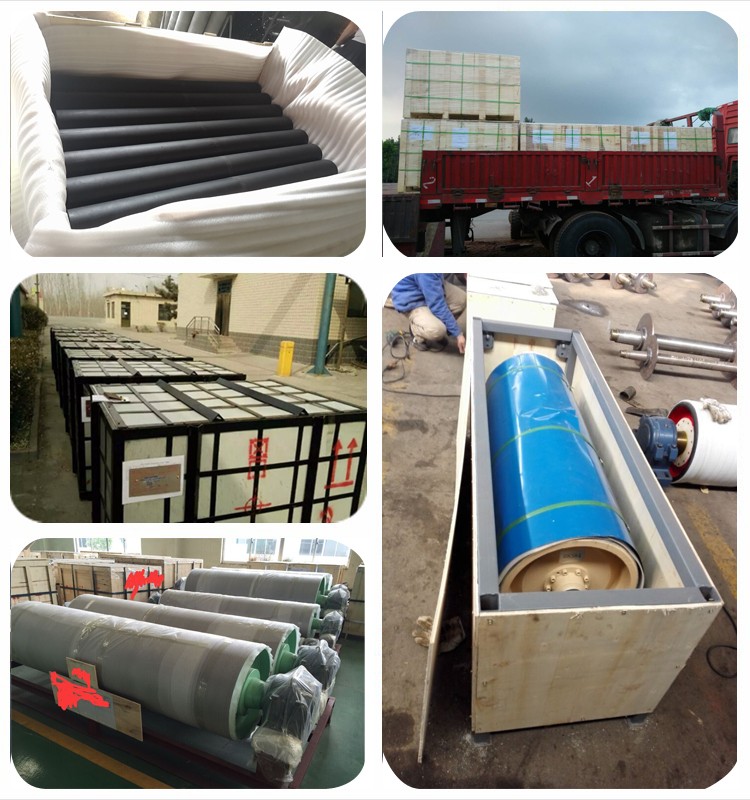

Packaging

We do careful packaging to ensure the good condition and successful delivery of the conveyor roller idlers and conveyor rollers and pulleys. We can do customer request, we can put customer logo, we can offer excellent Packing Safety.

Why Choose Us

1. With 30 years experience of hydraulic components in china.

2. Best manufacturing machinery, quality level, best price, best service.

3. We have very good and comprehensive after-sales service.

4. We have no MOQ for clients and tailor made to clients request for our huge inventory.

Our Service

Pre-sale service: we provide pre-sale in our first cooperation make clear your situation and give you some advice.

In-sale Service: We will track the production progress and quality, check the exact model and quantity one by one before delivering.

After-sale Service: We will provide a one year free warranty and lifetime maintenance. We will change all questions in 7*24hours if you buy from us.

Packing

Eternal Brand, Neutral or Customer's requires label.

Neutral carton or same as the Customer's requires, export standard carton.

All cartons should be packed into the pallets more carefully.

All of the productions are inspected carefully one by one by QC before delivery.

Payment term:

T/T 50% as deposit in advance, the balance should be paid before delivery.100% L/C is acceptable.Western Union and PayPal is acceptable.

Transportation: By sea; By air; By truck; By express (DHL,TNT,UPS,FEDEX)

Trading term: FOB, FCA, CIF

FAQ

Question 1: Did you accept products customization? Do they need mould fee?

Answer: Yes, we accept products customization. Need mould fee, because products usually need extra mould cost.

But we can return the mould fee when order reach a specific quantity.

Question 2: Can we get free samples?

Answer: The sample expense and freight expense will be borne by the buyers, and will be returned in the following orders.

Question 3: How long is normal production period for a 20-foot shipping container?

Answer: Accoring to the current productive capacity, usually need 3-14 days from producing to delivery. (not including customized products)

Question 4: What is the type of payment?

Answer: Usually, you should prepay 50% of the total amount. The balance should be paid before delivery. (We'll send photos of product to you for checking before delivery)

Question 5: How to guarantee the high quality?

Answer: We have testing department to make sure quality of every product, appearance and pressure test are good.

Product Categories : Conveyor System > Quartz Conveyor Roller